Understanding Incoloy 800HT Plates: Key Insights for Customers

Release time:

Incoloy 800HT plates are a type of high-performance alloy known for their excellent resistance to oxidation and carburization at high temperatures. This specific alloy, a variation of Incoloy 800, is particularly valued in industries where thermal stability and mechanical strength are critical. With its nickel-chromium-iron composition, Incoloy 800HT also incorporates additional elements such as t

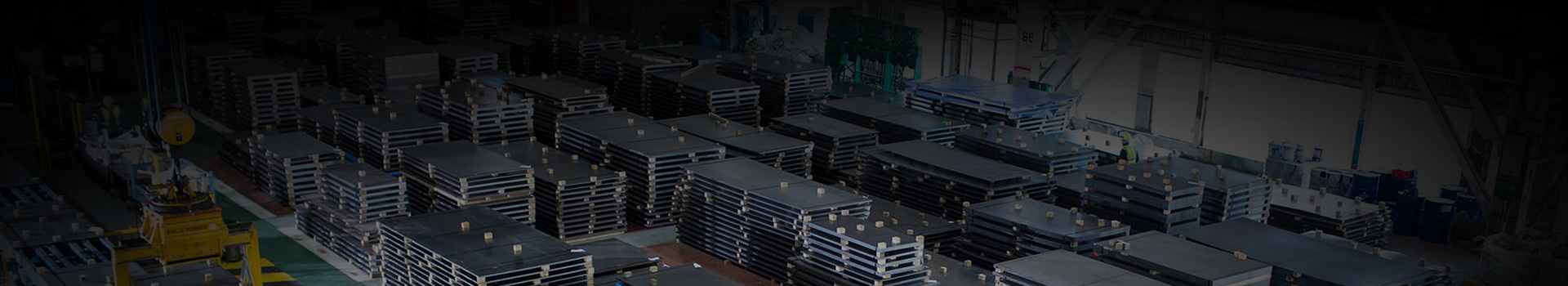

Incoloy 800HT plates are a type of high-performance alloy known for their excellent resistance to oxidation and carburization at high temperatures. This specific alloy, a variation of Incoloy 800, is particularly valued in industries where thermal stability and mechanical strength are critical. With its nickel-chromium-iron composition, Incoloy 800HT also incorporates additional elements such as titanium and aluminum, enhancing its high-temperature performance and overall durability.

One of the main features of Incoloy 800HT plates is their ability to withstand extreme temperatures, making them an ideal choice for applications in the petrochemical and energy sectors, particularly in furnaces and heat exchangers. The alloy’s unique composition provides outstanding resistance to both oxidation and carburization, which are common challenges faced in high-temperature environments. This characteristic not only prolongs the lifespan of components made from Incoloy 800HT but also ensures the reliability of equipment that operates under these conditions.

When considering Incoloy 800HT plate exporters, it’s important to look for suppliers who can guarantee the quality and specifications of their products. Reliable exporters should provide detailed documentation, including material test reports and certifications, which confirm that their Incoloy 800HT plates meet industry standards. This ensures that the material you receive is not only compliant but also suitable for your specific application needs.

Additionally, understanding the alloy's heat treatment process is crucial. Incoloy 800HT plates are typically subjected to a solution annealing process that optimizes their microstructure, which enhances their mechanical properties. This is a significant factor to keep in mind when sourcing from exporters, as the heat treatment can greatly affect the performance of the plates in real-world applications.

Another aspect worth noting is the environmental considerations surrounding the production and use of Incoloy 800HT. As industries continue to focus on sustainability, the demand for materials that can withstand harsh conditions while minimizing environmental impact is on the rise. Incoloy 800HT not only exhibits superior performance but can also contribute to energy efficiency in various applications, supporting a more sustainable approach in the metallurgy and energy sectors.

In summary, Incoloy 800HT plates are a valuable resource in high-temperature applications, providing significant benefits in terms of durability and resistance to environmental factors. When selecting an exporter, prioritize those who offer comprehensive quality assurance and in-depth knowledge about the alloy’s properties and applications. Understanding these aspects will help you make informed decisions that enhance your operational efficiency and material reliability.

One of the main features of Incoloy 800HT plates is their ability to withstand extreme temperatures, making them an ideal choice for applications in the petrochemical and energy sectors, particularly in furnaces and heat exchangers. The alloy’s unique composition provides outstanding resistance to both oxidation and carburization, which are common challenges faced in high-temperature environments. This characteristic not only prolongs the lifespan of components made from Incoloy 800HT but also ensures the reliability of equipment that operates under these conditions.

When considering Incoloy 800HT plate exporters, it’s important to look for suppliers who can guarantee the quality and specifications of their products. Reliable exporters should provide detailed documentation, including material test reports and certifications, which confirm that their Incoloy 800HT plates meet industry standards. This ensures that the material you receive is not only compliant but also suitable for your specific application needs.

Additionally, understanding the alloy's heat treatment process is crucial. Incoloy 800HT plates are typically subjected to a solution annealing process that optimizes their microstructure, which enhances their mechanical properties. This is a significant factor to keep in mind when sourcing from exporters, as the heat treatment can greatly affect the performance of the plates in real-world applications.

Another aspect worth noting is the environmental considerations surrounding the production and use of Incoloy 800HT. As industries continue to focus on sustainability, the demand for materials that can withstand harsh conditions while minimizing environmental impact is on the rise. Incoloy 800HT not only exhibits superior performance but can also contribute to energy efficiency in various applications, supporting a more sustainable approach in the metallurgy and energy sectors.

In summary, Incoloy 800HT plates are a valuable resource in high-temperature applications, providing significant benefits in terms of durability and resistance to environmental factors. When selecting an exporter, prioritize those who offer comprehensive quality assurance and in-depth knowledge about the alloy’s properties and applications. Understanding these aspects will help you make informed decisions that enhance your operational efficiency and material reliability.

Latest News