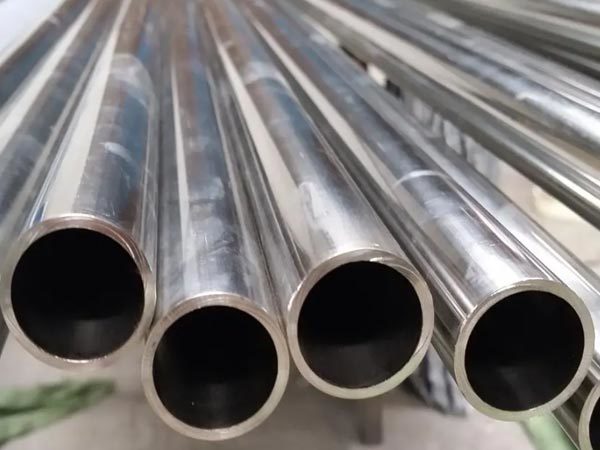

Tube Alloy 20

Classification :

Keywords:

Incoloy Alloy Pipe

|

Equivalent grade |

|

UNS N08020 |

|

Alloy 20 |

|

Title : Incoloy 020/Alloy20/UNS N08020 |

Available products:plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

|

Production standards |

|

|

Product |

ASTM |

|

Bar and wire |

B 408 |

|

Plate, Sheet and Strip |

A 240, A 480, B 463, B 906 |

|

Seamless pipes and fittings |

B 729, B 829 |

|

Welded pipe |

B 464, B 775 |

|

Welded fittings |

B 468, B 751 |

|

Solder connection |

B 366 |

|

Forged frying pipe flanges and forgings |

B 462 |

|

Forged billets and bars |

B 472 |

Chemical composition

|

% |

Fe |

Ni |

Cr |

Cu |

Mo |

C |

Mn |

Si |

P |

S |

Nb+Ta |

|

Min |

balance |

32.0 |

19.0 |

3.0 |

2.0 |

|

|

|

|

|

8*C |

|

Max |

|

38.0 |

21.0 |

4.0 |

3.0 |

0.07 |

2.00 |

1.00 |

0.045 |

0.035 |

1.00 |

Physical properties

|

Density |

8.08 g/cm3 |

|

Melting |

1357-1430℃ |

Alloy20 characteristics

Alloy N08020 is a nickel-iron-chromium austenitic alloy with excellent resistance to acid attack, pitting and crevice corrosion as well as chloride-containing acids and chemicals, general corrosion and intergranular corrosion. The alloy combines excellent corrosion resistance, ease of fabrication and enhanced mechanical properties.

Alloy N08020 is also known as Carpenter 20, Incoloy and 20Cb-3.

N08020 is a niobium stabilized low carbon austenitic nickel-iron-chromium alloy containing copper and molybdenum.

Advantage

Excellent resistance to sulfuric acid and phosphoric acid

Good resistance to intergranular corrosion

Extremely resistant to stress corrosion cracking caused by chloride ions

Good resistance to pitting and crevice corrosion

Good mechanical properties at room temperature and at elevated temperatures up to about 500°C (930°F)

Product application areas of Alloy20

Alloy 20 is an iron-based austenitic alloy developed to resist sulfuric acid corrosion. It has excellent resistance to sulfuric acid corrosion; it has strong resistance to phosphoric acid, nitric acid and chloride environments, chloride stress corrosion, pitting corrosion and crack corrosion. Therefore, alloy 20 has the name of anti-corrosion alloy.

It has a wide range of applications: such as: chemical, food, medicine, power production and plastics industries will use it. Resistance to pitting corrosion and chloride corrosion, stress corrosion cracking problems, etc., alloy 20 is often used.

FAQ

RELATED PRODUCTS

GET A FREE QUOTE