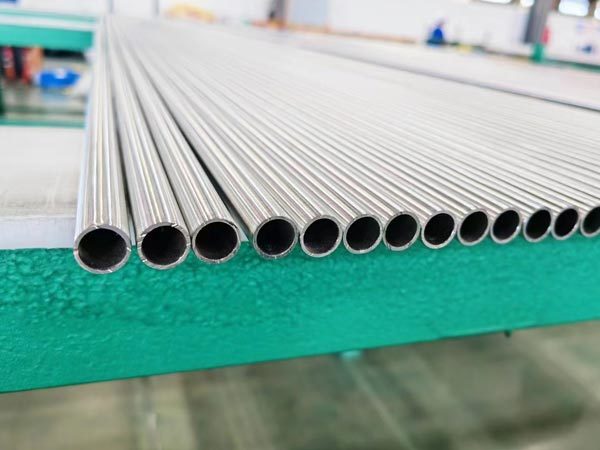

Tube Hastelloy G35

Classification :

Keywords:

Hastelloy Alloy Pipe

|

Equivalent grade |

|

UNS N06035 |

|

DIN W. Nr. 2.4643 |

|

Title:Hastelloy G35/UNS N06035/Alloy G35 |

Available products: plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

Chemical composition

|

% |

Ni |

Cr |

Mo |

Fe |

Cu |

W |

C |

Mn |

Si |

Co |

Al |

|

min |

58 |

|

8.1 |

|

|

|

|

|

|

|

|

|

max |

|

33.2 |

|

2 |

0.3 |

0.6 |

0.05 |

0.50 |

0.6 |

1 |

0.4 |

Physical properties

|

density |

8.22 g/cm3 |

|

Melting |

1370-1400℃ |

Introduction

Hastelloy G35 is a nickel-chromium-molybdenum alloy renowned for its exceptional corrosion resistance in various aggressive environments. This alloy offers superior resistance to localized corrosion, such as pitting and crevice corrosion, making it ideal for applications in chemical processing, petrochemical, and marine industries. Additionally, Hastelloy G35 exhibits excellent mechanical properties and weldability, making it versatile for use in critical components subjected to high temperatures and corrosive conditions. Its reliability and performance have established it as a preferred choice for demanding applications where durability and corrosion resistance are paramount.

Advantages of Hastelloy G35

1. Exceptional corrosion resistance in diverse aggressive environments.

2. Superior resistance to localized corrosion, including pitting and crevice corrosion.

3. High strength and toughness for demanding industrial applications.

4. Excellent weldability and fabrication characteristics for ease of manufacturing.

5. Versatile material suitable for various chemical processing and petrochemical applications.

6. Reliable performance in high-temperature and corrosive conditions.

7. Wide availability and proven track record in critical industries.

8. Low risk of sensitization, ensuring long-term reliability in corrosive environments.

Application field

Hastelloy G35 finds application in various industries where corrosion resistance and high-temperature performance are crucial. Commonly used in chemical processing, petrochemical, and oil and gas industries, it is employed in reactors, vessels, and piping systems exposed to aggressive chemicals and elevated temperatures. Additionally, Hastelloy G35 is utilized in the pharmaceutical industry for equipment involved in drug production and in the pulp and paper industry for components subjected to corrosive environments. Its versatility and reliability make it indispensable for critical applications where durability and corrosion resistance are paramount.

FAQ

RELATED PRODUCTS

GET A FREE QUOTE