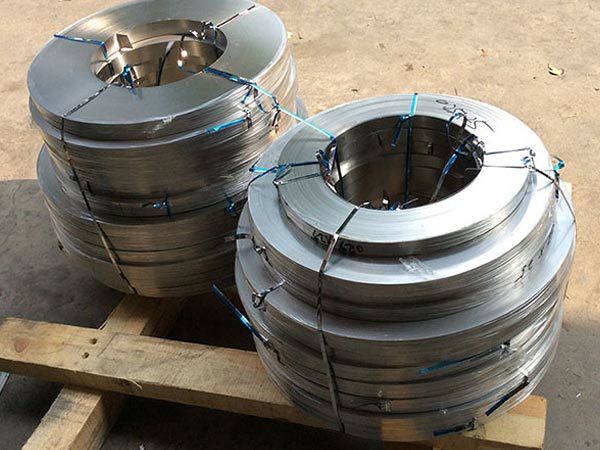

Strip N6

Classification :

Keywords:

pure nickel Strip

|

Equivalent grade |

|

UNS N02200 |

|

DIN W. Nr. 2.4060, 2.4066 |

|

N6 |

|

Title : UNS N02200/N6/Ni200 |

Available products: plate/sheet, bar/rod, pipe/tube, strip, fittings, wire, forging, fastener, customization

|

Production standards |

|

|

Product |

ASTM |

|

Bar |

B 160 |

|

Sheets, Sheets and Strips |

B 162, B 906 |

|

Seamless Pipe and Fittings |

B 161, B 829 |

|

welded pipe |

B 725, B 775 |

|

Welded pipe fittings |

B 730, B 751 |

|

Welded connectors |

B 366 |

|

Forging |

B 564 |

Chemical composition

|

% |

Ni |

Fe |

C |

Mn |

Si |

S |

Cu |

|

Min |

99.5 |

|

|

|

|

|

|

|

Max |

|

0.40 |

0.15 |

0.35 |

0.35 |

0.010 |

0.25 |

Physical properties

|

Density |

8.89 g/cm3 |

|

Melting |

1435-1446℃ |

Nickel 200 Material Properties

Nickel 200 (N6) has excellent corrosion resistance, high electrical vacuum performance and electromagnetic viewing performance, and is widely used in chemical, mechanical and electronic, food and other fields. Pure nickel has excellent welding performance and processing performance, and can be processed into pipe, rod, wire, strip, and foil products. It is one of the most widely used materials in industry. It has good mechanical properties and excellent corrosion resistance in many corrosion-resistant environments, especially caustic soda corrosion.

Nickel 200 (N6) is a commercially processed pure nickel that is effective against corrosion in a variety of chemical environments. It can also be used under oxidizing conditions to passively form an oxide film, making it extremely resistant to alkali metal corrosion. Nickel 200 (N6) is limited to use below 315°C, because the increase in temperature will cause graphitization, which will seriously damage its quality. In this case, Nickel 201 is required. It has a high Curie temperature and good magnetic properties. And its thermal conductivity and electrical conductivity are higher than nickel alloys.

Advantage

1. Excellent corrosion resistance in various environments.

2. High thermal and electrical conductivity properties.

3. Exceptional resistance to alkalis and neutral salts.

4. Good mechanical properties even at elevated temperatures.

5. Easy to fabricate, weld, and form into desired shapes.

6. Low gas content ensures minimal risk of embrittlement.

7. Resistant to stress corrosion cracking and pitting corrosion.

8. Suitable for use in chemical processing and marine applications.

9. Long-term durability and reliability in aggressive environments.

10. Cost-effective compared to other high-performance alloys.

Nickel 200 (N6) material application areas

In food processing equipment, salt refining equipment. However, the equipment and the like required to manufacture industrial sodium hydroxide under high temperature conditions above 300°C. In the field of materials, it can be used to manufacture plates, strips, round bars, and welded pipes.

Food and synthetic fibers; electrical and electronic components; aerospace and missile components; chemical storage tanks.

FAQ

RELATED PRODUCTS

GET A FREE QUOTE